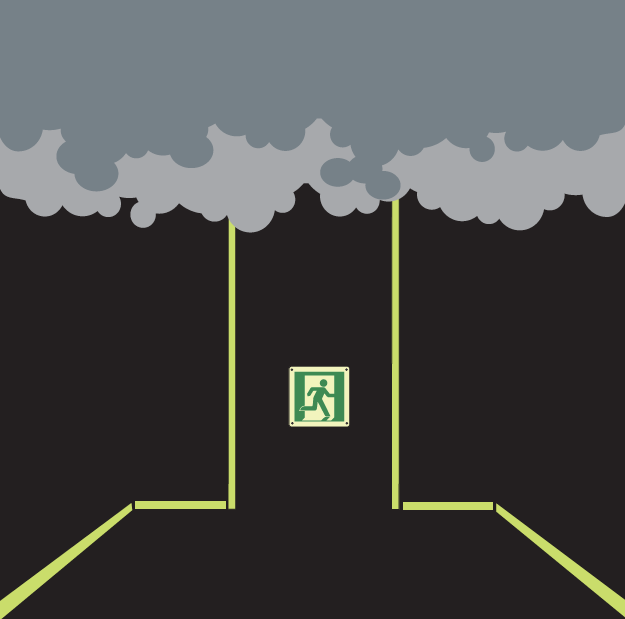

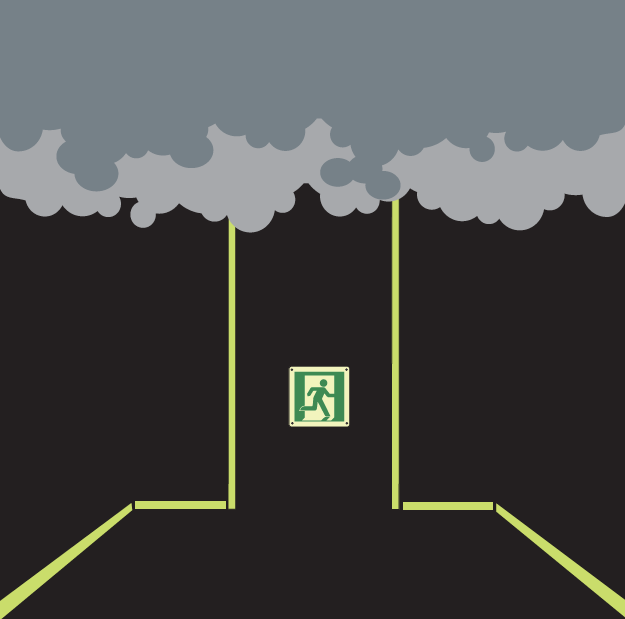

Ecoglo has just released it’s design strategy to deal with smoke. It’s so simple but it seems to annoy the incumbent electrical emergency lighting industry. Not sure why? $$$$$

Download it here:

Ecoglo has just released it’s design strategy to deal with smoke. It’s so simple but it seems to annoy the incumbent electrical emergency lighting industry. Not sure why? $$$$$

Download it here:

While I was at TEDx Christchurch on Saturday it was great to see Ecoglo installed as the emergency lighting solution at the rebuilt Isaac Theatre Royal. Post earthquake Christchurch rebuilds have been very focused on ensuring that emergency systems are resilient and outdoor sectors of evacuation routes have traditionally been a big problem – high capital cost, higher maintenance costs and even higher failure rates. Now all SOLVED BY ECOGLO!

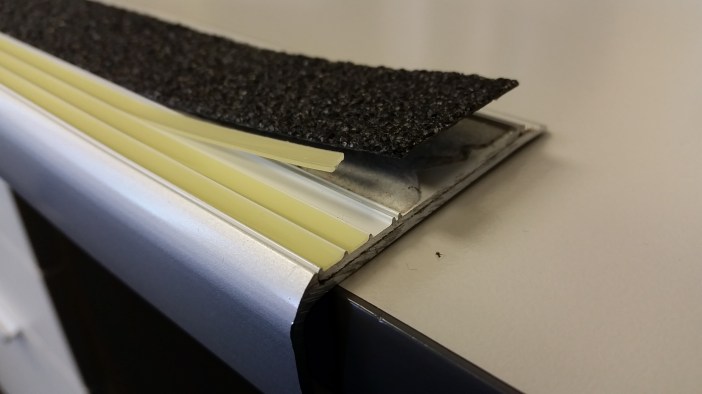

They say imitation is the greatest form of flattery but this is ridiculous!

Last year I came across this Ecoglo imitation (with yellow anti-slip) in a large Australian stadium. It had been installed for about 8 months and was clearly produced to look like an Ecoglo extrusion. The problem was that after 8 months the product was falling to bits! Now an imitation with black anti-slip has surfaced bidding for a large facility and the samples are showing the same weaknesses as seen in the stadium product last year.

Although the impostor has created an Ecoglo lookalike they can’t replicate the patented Ecoglo manufacturing process which creates its unique durability, essential in emergency lighting systems. A quick check of independent testing documentation would sort this out.

The Photoluminescent Lighting Council (PLC) was formed in October 2015 to advance the use of photoluminescent (PL) technology in exit sign and emergency visibility solutions.

The PLC is currently working on a Best Practice for the “Inspection & Maintenance of Exit Signs”. As building codes are modified to recognise PL exit signs we need to ensure that the initiative doesn’t get bogged down with standards that are full of outdated electrical lighting terminology and procedures.

For a full rundown of the PLC objectives take a look at:

http://www.plcouncil.com.au/

If you want to be kept up-to-date with the development of the Best Practice you can join the PLC through the Members’ page on the website or send your input to info@plcouncil.com.au.

The new National Construction Code (NCC 2016) came into force on 1 May and the outdated references to “emergency lighting” have been deleted from Part E4 of the code with the section now being titled “Visibility in an Emergency, Exit Signs, and Warning Systems”.

An independent report released in 2013 indicated that 70% of the $1.1 billion of productivity gains delivered by Australian Building Codes Board (ABCB) reforms were derived from performance based building code. The report also identified that future gains are possible with an increased use of performance codes and the wording of the new NCC 2016 is a step towards achieving these gains.

The ABCB has previously noted that “a prescriptive mindset continues to exist in the majority of industry practitioners and regulators”. There are a variety of reasons why this mindset is such a barrier. Old habits, influence of vested interests and the ease of “tick the box” solutions are among those reasons but the old code wording hasn’t helped.

The NCC 2016 changes mean that Ecoglo can provide Performance Solutions for photoluminescent signs to replace the old technology electrical signs and batteries. This innovation means that your next sustainability initiative can also be a big budget winner. There are significant electricity and maintenance savings as well as no nasty batteries to have to bury in someone else’s back yard!

Ecoglo Performance Solutions can also be used to solve problems with old and tired emergency lighting systems with Ecoglo’s renowned durability especially useful in outdoor situations.

Hard data shows that Ecoglo photoluminescent solutions, when compared to the electrical equivalent, can be less than 30% of the initial capital cost and 7.5% of the 30 year life cost.

Ecoglo has nearly 20 years global experience engineering emergency visibility systems in a wide range of facilities and we can show you how to capitalise on the new NCC Performance Solution approach.

Both NZ and Australia have now changed their building codes to allow photoluminescent systems to replace electrical emergency lighting and electrical exit signs. NZ made the code changes in 2007 and 2012. Australian changed its exit sign code in 2014 and the new National Construction Code (NCC) addressing emergency lighting will come into force on May 1.

In NZ we’re seeing that electrical solutions cost 8 to 10 times the cost of a photoluminescent (PL) solution. On that basis the NZ economy has saved up to $19 million by replacing electrical with PL lighting and signs – and a good chunk of that is taxpayers’ money.

Can Australia realise similar efficiency gains when NCC 2016 comes into force?

We know that it will depend on those in compliance and consulting being able to resist the pressure that they will get from the electrical industry. If our NZ experience is repeated in Australia, every time we make $50 the electrical industry will lose $500 so there will be a lot of pressure!

The Australian Building Codes Board (ABCB) has confirmed that it is serious about accessing $1.1 billion of productivity gains for the construction sector.

The new National Construction Code (NCC 2016) was released this week and the outdated references to “emergency lighting” have been deleted from Part E4 of the code with the section now being titled “Visibility in an Emergency, Exit Signs, and Warning Systems”.

These changes mean that photoluminescent products can now be used to provide solutions rather than the old electrical approach.

The ABCB’s objective in making these changes is to encourage innovation with a performance based design approach. They have previously noted that “a prescriptive mindset continues to exist in the majority of industry practitioners and regulators”. There are a variety of reasons why this mindset is such a barrier. Old habits, influence of vested interests and the ease of “tick the box” solutions are among those reasons but the wording of the code has not helped the situation.

The ABCB have further made their point by replacing the term “Alternative Solution” with “Performance Solution”. The old term may have suggested that the Deemed-to-Satisfy (DtS) prescription was somehow preferred to the alternatives but there is now clarity that the Performance Requirements are the mandatory components of the code. The amended terminology has brought into focus that a Performance Solution satisfies the code and the DtS prescription is just one of many approaches that can be used.

There has been a long history of industry incumbents using the DtS approach to limit options by pointing to the “Deemed to Satisfy” (DtS) and saying “that’s the code, new technologies don’t fit into the DtS therefore they don’t comply with the code.”

NCC 2016 is a step towards overcoming this mindset and provides an opportunity for designers to deliver greater value to clients by creating performance solutions that are cost effective and sustainable.

It’s been said that the Stone Age didn’t end because they ran out of stones. Something better came along and disrupted the status quo. Electrical manufacturers and distributors continual resistance to the advance of photoluminescent (PL) technology is more than a little pre-historic but the efficiencies of PL systems can’t be stopped.

Here’s why consultants are specifying PL more and more.

There are an estimated 2,400 schools in New Zealand with an average 12 electrical exit signs per school. If the life of those electrical signs is around 5 years, then 5,760 replacement signs are needed each year. At $300 for product & labour each time someone is called out to replace a sign the cost is $51 million over 30 years – sounds like a profitable industry doesn’t it!

Now if all 28,800 signs were installed as PL then the 30 year cost would be $1.73 million. That’s a saving of $50 million for taxpayers and $50 million that can be targeted directly at education.

So they can keep swinging that stone adze but, like bronze and iron, there’s a new technology that’s going to slowly and surely gain acceptance and consign blinkered thinking to history.

Ecoglo recently completed a review of the emergency exit sign system in a sorting facility of a large Australian logistics company.

The review was triggered by a 2014 change to the Australian Building Code which recognised that photoluminescent (PL) signs were able to replace the traditional electrical alternatives.

The exercise looked at decommissioning all of the electrical exit signs and replacing them with PL equivalents. Although the primary driver was to improve the company’s sustainability profile they were very pleased to find that there were also significant financial savings.

The 10,000 square metre facility had 32 electrical exit signs and the cost of decommissioning these, replacing them with PL signs, and the associated permits and certification was just over $10,000. The ongoing electricity and maintenance costs of the electrical signs was estimated at $70 per sign per annum. The PL signs used existing lighting to charge so had no electricity cost and minimal inspection and maintenance costs. This meant that the project had a payback period of 3 years and when the Net Present Value of the project was calculated over 30 years there was a $30,837 saving for the logistics company.

These numbers are not chicken feed and when you look at the comparisons between electrical and PL in new buildings, rather than retrofit, the difference between the costs escalates.

It’s no wonder that the electrical industry is squirming around trying every trick in the book to protect their revenue streams.

The Australian Building Codes Board (ABCB) has made a significant step towards achieving $1.1 billion of productivity gains in the construction sector. Among the planned changes is a proposal to alter the code for emergency lighting to be more performance based. The proposed change to the National Construction Code (NCC) will use terms such as “visibility in an emergency” rather than the somewhat archaic “emergency lighting”.

This will allow alternative technologies, such as Ecoglo’s photoluminescent systems, to be used more easily. Already manufacturers and distributors of electrical emergency lighting are weeping and wailing about the proposals – no doubt their industry magazines and other propaganda tools will soon resume their railing against progress. The ABCB, in their overview supporting the changes, has identified that “a prescriptive mindset continues to exist in the majority of industry practitioners and regulators”. There are a variety of reasons why this mindset is such a barrier. Old habits and the ease of “tick the box” solutions are among the reasons this mindset endures

Alternative photoluminescent technology is the newby. The incumbent electricity suppliers have had years of lunches and trips to the footy to build relationships where they put their case using partial science and partial truths to block competition.

The “Deemed to Satisfy” solution (known in NZ as the Acceptable Solution) is only one of many ways to meet the building code. The incumbents point to the “Deemed to Satisfy”(DtS) and say “that’s the code, new technologies don’t fit into the DtS therefore they don’t comply with the code.” If this attitude to progress was widespread we’d all still be reading by candle light!

According to the ABCB background document this short sighted behaviour is contributing to a $1.1 billion cost to the Australian economy, a number that is too great to ignore.